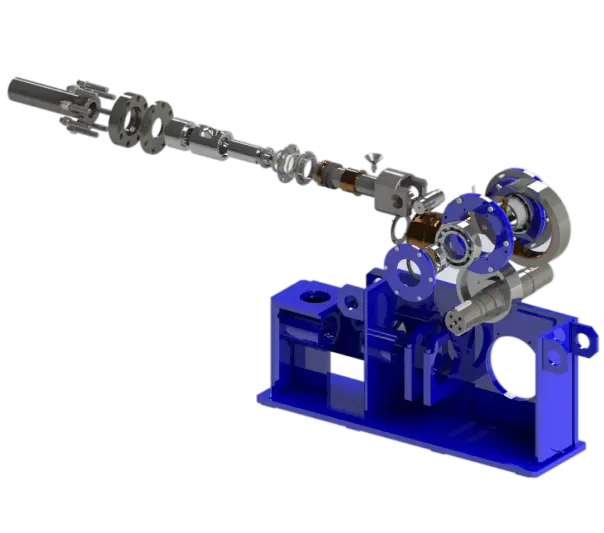

Briquetting press PB-48 works successfully in a complex with the products of other manufacturers: shredders of incoming raw materials, drying complexes, mechanisms for supplying raw materials and unloading the finished product.

We will offer various options for the layout of the entire briquetting line on the areas proposed by the customer.

We will provide technical and accompanying documentation for the entire complex of equipment, all nodes, aggregates and components.

Our company is constantly working on improving the design, manufacturing technology, improving reliability, durability, maintainability, manufacturing quality, and assembling equipment.